ABOUT US

History

Founding of the sole proprietorship Ricci&Mottaz Décolletage

et Mécanique ![]()

![]() Purchase of the first cam-type automatic lathes (Tornos, Petermann, Rotarix)

Purchase of the first cam-type automatic lathes (Tornos, Petermann, Rotarix)

Establishment of Ricci & Mottaz Sàrl ![]()

Acquisition of the first CNC lathe (STAR) ![]()

![]() Sale of all remaining cam-type lathes

Sale of all remaining cam-type lathes

Purchase of the first closed-bath parts washer (ILSA) ![]()

![]() Purchase and first renovation of the Evalins building in Moutier

Purchase and first renovation of the Evalins building in Moutier

![]() Relocation to the new Evalins premises in Moutier

Relocation to the new Evalins premises in Moutier

Purchase and installation of the ERP software Logyplan ![]()

Acquisition of a HAAS DT-1 machining center ![]()

Acquisition of the inspection software Qualigest ![]()

Acquisition of the first fixed-headstock lathe (Miyano BNJ51SY6) ![]()

![]() Acquisition of a new parts cleaning machine (Modified Alcohol / ILSA)

Acquisition of a new parts cleaning machine (Modified Alcohol / ILSA)

![]() Acquisition of two STAR SR20J machines

Acquisition of two STAR SR20J machines

Acquisition of a Hanwha XD07 machine ![]()

![]() 100% takeover of the company by Mr. Laurent Mottaz

100% takeover of the company by Mr. Laurent Mottaz

![]() Acquisition of Fox4Work storage software

Acquisition of Fox4Work storage software

![]() Acquisition of a Tsugami MO8SYE-II CNC lathe (65 mm spindle feedthrough)

Acquisition of a Tsugami MO8SYE-II CNC lathe (65 mm spindle feedthrough)

![]() Installation of solar panels

Installation of solar panels

![]() 30th anniversary of Ricci & Mottaz Sàrl

30th anniversary of Ricci & Mottaz Sàrl

More than a service provider, our aim is to be a partner at your side

Our philosophy

The relationship at the heart of our process

Ricci & Mottaz deploys its activities based on strong values that guide each of its choices: to accompany its clients in traditional or innovative projects that combine an excellent balance between quality, price and deadline.

There is nothing like excellent relations to care for and maintain the trust of its customers. Ricci & Mottaz therefore attaches great importance to the processing of each request and responds with particular attention. This approach aims to ensure the continued relevance of the products manufactured and to preserve the company's reputation, from the design to the finishing stages.

Our expertise

From tradition to innovation

Quality first and foremost

At RICCI & MOTTAZ, quality is our top priority. We understand that precision and reliability are crucial for our clients, which is why we have implemented stringent quality control processes.

Raw material selection: We start by choosing only top-grade materials that meet our strict quality criteria.

In-process inspections: Throughout the bar turning process, our technicians perform regular checks to ensure each part meets the required specifications.

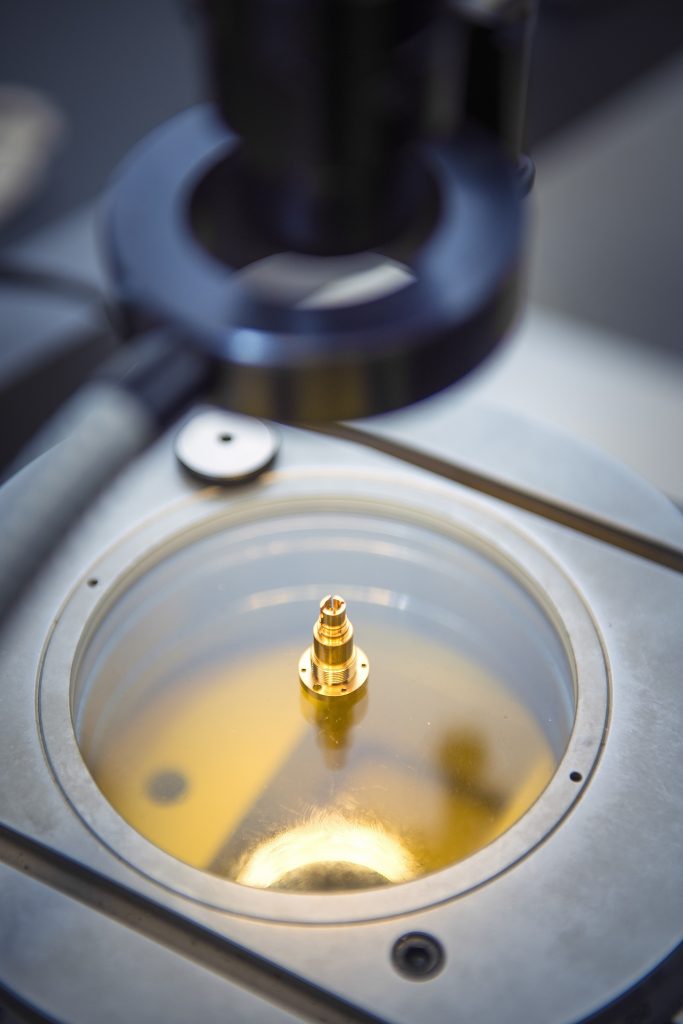

Final inspection: Before shipping, every product undergoes a detailed final inspection. Using high-precision measuring tools, we verify dimensional parameters and visual appearance to ensure full compliance.

We are also committed to continuous improvement. Through regular training and the adoption of the latest technologies, we ensure our products stay at the forefront of the industry.

Our company is certified to ISO 9001.

This allows us to meet our customers' expectations on an ongoing basis through the implementation of a Quality Management System (QMS), which enables us to manage and continuously improve all our processes.

Constantly optimizing the quality of our products and services is a strong motivation for our team.